PRODUCTS

IH Stainless Steel Centrifugal Cheemical Pump

Category:

The main products include QB, 2QS steam reciprocating pump series, DG, D horizontal multi-stage centrifugal pumps, JGGC efficient vertical boiler feed pumps, LG, DL high-rise buildings water feed pumps, R hot water circulation pump series, IS, IH single-stage centrifugal pump series, DB, W vortex pump series, with a total of nearly 20 series, and more than 400 varieties.

Keywords:QB, 2QS steam reciprocating pump series, DG, D horizontal multi-stage centrifugal pumps

Type IH pump is single-stage and single-suction (axial suction) corrosion resistant centrifugal pump, which is suitable for pumping corrosive liquid without solid particles or other liquid whose consistency is similar to that of clean water. The temperature of medium is -20~105℃, if necessary, cooling measure can be taken to reach a higher temperature. It applies to petroleum, chemical, metallurgical, power, paper making,foodstuff, pharmaceutical, and synthetic fiber industry, etc.

Type IH pump is designed by National pump Industry according to ISO Standard, which has many advantages such as wider range of properties, higher efficiency and convenient maintenance. Its efficiency is average higher 2% than type F pump can be described as energy saving product popularized by the government.

Type IH serial pump have 40 basic types, among which there are 33 double speed (2900 and 11450r/min) can reach 112 specifications after cutting impeller diameter of type A and B.

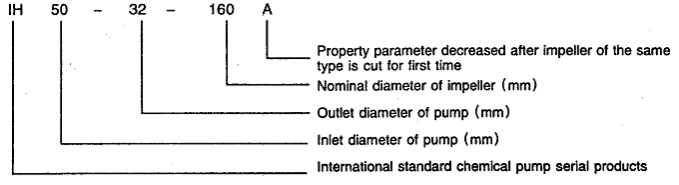

Model meaning:

Contact Us

More Products

Contact us to learn more about our business solutions

Fill out the form below to receive news and industry insights about emerging products that are sent directly to your inbox