NEWS CENTER

Structure characteristics and introduction of quality 2QS Steam Reciprocating Pump

Time:

2021-12-30

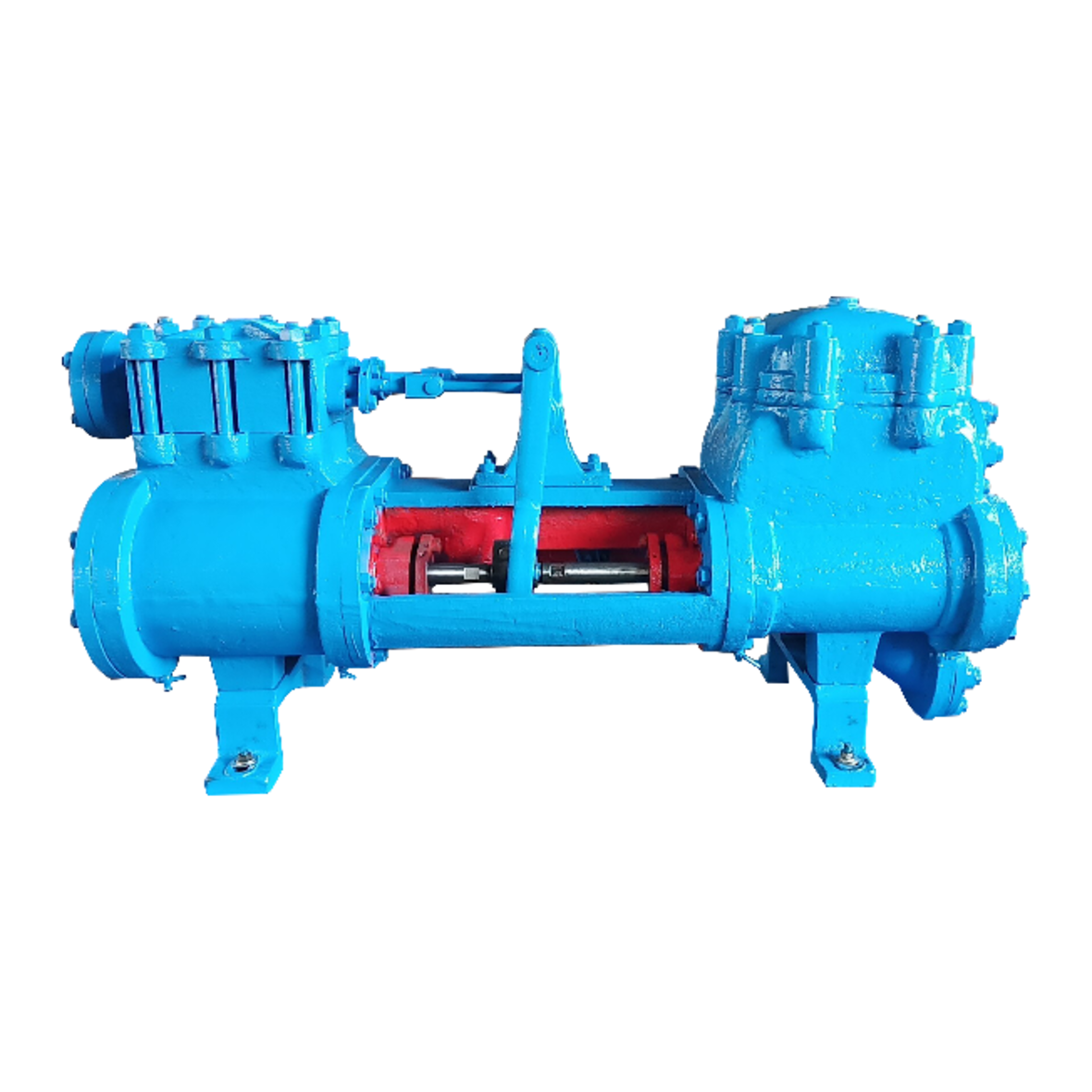

The quality 2QS Steam Reciprocating Pump is a kind of pumping equipment that uses steam as power and works according to the pump principle. It is mainly used for medium and small boiler water supply, oil refinery transportation of petroleum products, mine drainage, etc. The working pressure of the cylinder of various steam reciprocating pumps is 1.4Mpa, and the discharge pressure is 1.7Mpa. It is suitable for saturated steam and superheated steam, and the temperature does not exceed 200℃. The structural characteristics and introduction of quality 2QS Steam Reciprocating Pump are shown below:

1. The quality 2QS Steam Reciprocating Pump is a double-cylinder, double-acting, horizontal pump, directly driven by steam. The mechanical structure can be divided into the cylinder part and the hydraulic cylinder part, which are connected by the middle section, and the center frame is installed on the middle section. For the convenience of processing, the piston rod is divided into two sections and connected into a whole with a coupler.

2. Liquid cylinder part:

The cylinder body is made of cast iron with a cylinder liner inside, and a bracket is connected under the cylinder body. There are 8 flat valves on the upper part of the cylinder, 4 are suction valves and 4 are discharge valves. The valves and valve seats are made of cast copper.

3. Cylinder part:

The cylinder block is made of cast iron, the lower part is connected with a bracket to fix the foundation, the upper part of the cylinder is equipped with a staggered steam box, and there are two flat staggered steam valves inside to control the entry and discharge of steam. Through the swing of the lever and the reciprocating movement of the staggered steam rod, the piston is pushed to make a reciprocating movement.

4. Lubrication of quality 2QS Steam Reciprocating Pump:

All parts are manually lubricated. The lubricating oil for the flat valve and piston ring is supplied by the thin oil cup on the cylinder, and the lubrication of other parts such as the pendulum rod of the center frame and the piston rod is manual lubrication.

5. Middle section:

The middle section is a connecting mechanism that connects the cylinder and the hydraulic cylinder into a whole. There are stuffing boxes at both ends and a stuffing gland to adjust the tightness of the stuffing. The stuffing can be made of oil-impregnated asbestos rope.

More News