NEWS CENTER

What are the structural forms of Horizontal Multistage Pump

Time:

2021-11-25

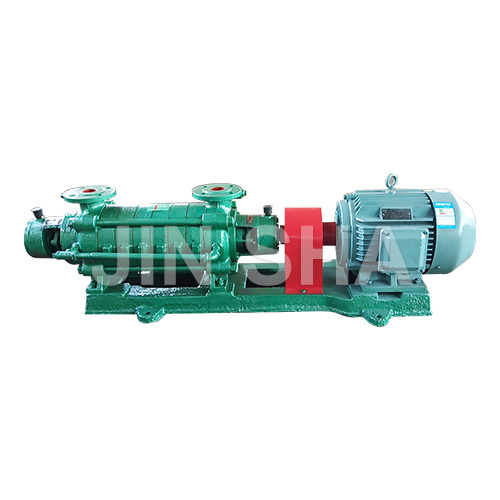

With the development of society, Horizontal Multistage Pump has been widely used in various industries. The scope of application of multi-stage centrifugal pumps is mostly water, corrosive liquids, hydrochloric acid, etc., with the advantages of large displacement and high lift, so the parameter range can meet the requirements of most enterprises. It is of great significance in the treatment of mine groundwater in mining enterprises. At present, the structure of Horizontal Multistage Pump in my country is mainly divided into two types. Next, let's learn about the structure of Horizontal Multistage Pump, so that you can have a better understanding of Horizontal Multistage Pump.

There are currently two types of Horizontal Multistage Pump structures on the market. One is a segmental type and the other is a double-shell type. The pump body of the double-shell type multistage centrifugal pump is a double-layer structure, and there is space between the inner and outer shells. It is filled with high-pressure water, and the inner casing is subjected to external pressure. Under the action of fluid pressure, the joint surface of the pump body has a good sealing performance. The force on the outer casing is equal to the internal pressure of the pump water pressure. The whole of the pump is put into the barrel, so the maintenance process is relatively simple. There is also a dedicated inner shell device in the outer cylinder, and it has the function of a flow channel. Set the cylinder cover on one side of the outer cylinder, press out the internal pressure, place the inner shell on the outer cylinder, and place the corresponding gasket on the contact part of the two to seal the suction chamber space Degree to maintain.

The inner shell of another Horizontal Multistage Pump is segmented, and the technology used is a guide vane pressurized water chamber, and its impellers are arranged in the same direction. In the entire horizontal multi-stage centrifugal pump, the control of the balance axial force is mainly to use the function of the three-gap balance disc. This structure can achieve a relatively stable axial force under the condition of small size, and also has the function of anti-wear. Therefore, the reliability and stability during the working process are high. During the whole work process, the leaked water will be introduced into the suction port of the pump through the balance pipe, and the corresponding thrust bearing is equipped. The two sets of sliding bearings are equipped to support the rotor, and the corresponding bearing housings are fixed on the inner cylinder. The sliding bearing mainly adopts pressure lubricating oil for compulsory lubrication, while the box seat adopts a labyrinth for good sealing. With the development of technology and the continuous research of water pump companies, another segmental horizontal multistage centrifugal pump has become popular on the market-self-balancing horizontal multistage centrifugal pump. This horizontal multistage centrifugal pump has been cancelled. The balance device realizes self-balance through the structure design and the setting of the symmetrical positive and negative impellers. The maintenance-free period is longer, the efficiency is higher, the replacement rate of consumables is low, and its economic effect is higher than the traditional horizontal multi-stage centrifugal pump.

More News