NEWS CENTER

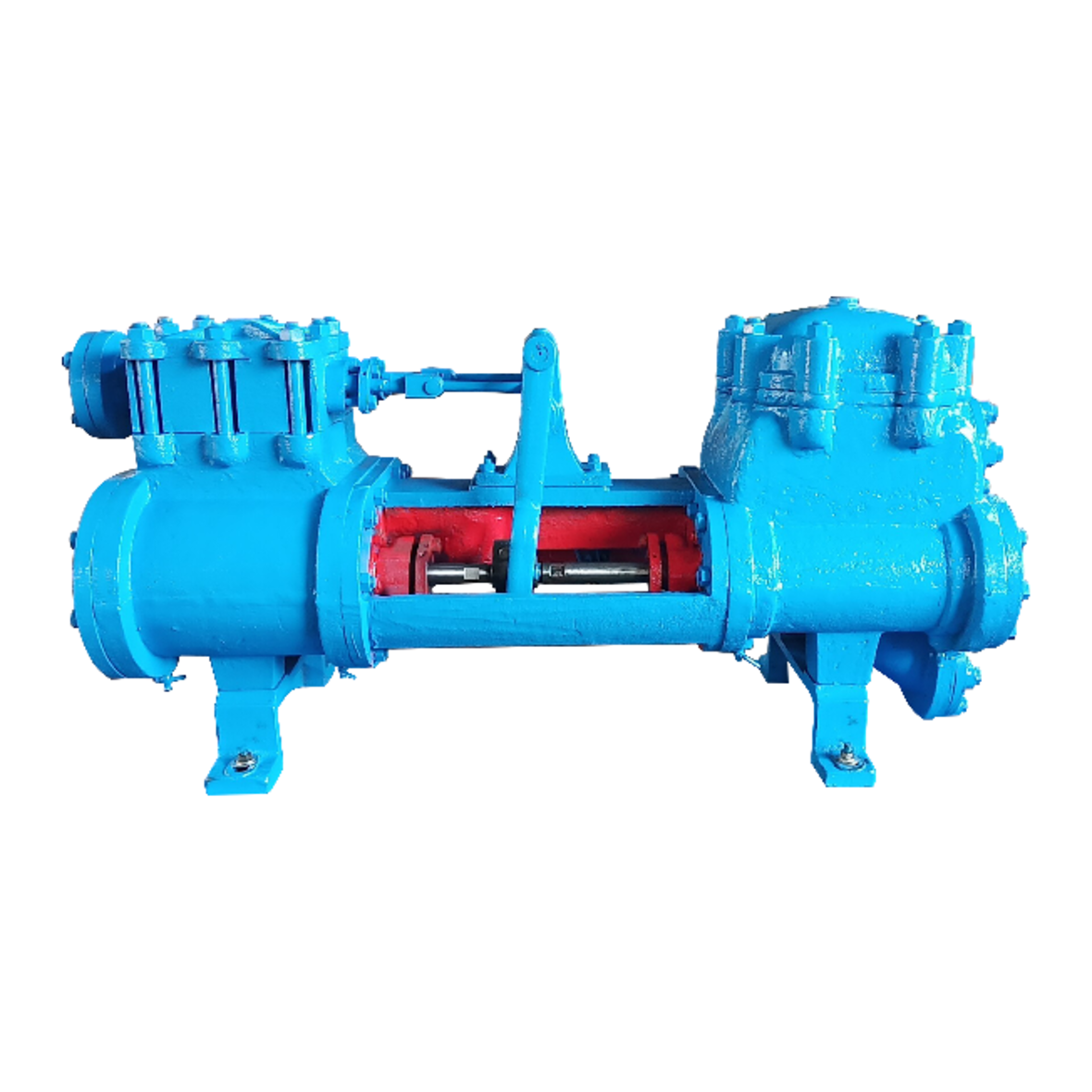

The structure and working principle of customized Steam Reciprocating Pump

Time:

2021-12-23

The principle of a customized Steam Reciprocating Pump is basically the same as that of a flexible reciprocating pump. The important difference is the driving method. The steam reciprocating pump does not have a crank connecting rod mechanism. The steam reciprocating pump is controlled by the steam distribution mechanism of the steam pressure and flow. Then the steam acting on the cylinder piston drives the reciprocating movement of the cylinder piston, so that the pressure in the cylinder is changed to match the opening and closing of the inlet and outlet valve groups to deliver liquid.

Steam Reciprocating Pump is a kind of liquid conveying machinery first used in actual engineering, which is a kind of positive displacement pump. Let's take a look at the structural features and working principle of steam reciprocating pump.

The structure and working principle of customized Steam Reciprocating Pump

A customized Steam Reciprocating Pump is a positive displacement pump in which pistons, plungers or diaphragms reciprocate in the pump cylinder to alternately increase and decrease the working volume in the cylinder to deliver liquids or pressurize them. Reciprocating pumps are divided into three types: piston pump, plunger pump and diaphragm pump according to different reciprocating elements.

Features of customized Steam Reciprocating Pump

The important features of customized Steam Reciprocating Pump are: ① High effectiveness and wide efficient area.

②It can reach a very high pressure, and the pressure change hardly affects the flow rate, so it can supply a constant flow rate.

③With self-priming ability, it can transport liquid and gas mixtures, and the specially designed one can also transport mud, concrete, etc.

④The flow and pressure have larger pulsation, especially for single-acting pumps. Due to the acceleration of piston movement and the discontinuity of liquid discharge, the pulsation is greater. It is usually necessary to set up an air chamber on the discharge pipe (sometimes on the suction pipe) to make the flow more uniform. The use of double-acting pumps and multi-cylinder pumps can also significantly improve the unevenness of the flow.

⑤The speed is low, the size is large, and the structure is more complex than the centrifugal pump. Special pump valves are required, and the production cost and installation cost are high. Piston pumps are mainly used for water supply, and manual piston pumps are a widely used household water pump. The plunger pump is used to supply high-pressure liquid sources, such as the high-pressure water supply of a hydraulic press. Both it and the piston pump can be used as drilling mud pumps and oil well pumps in oil fields. Diaphragm pumps are especially suitable for transporting highly toxic, radioactive, and corrosive liquids, precious liquids and liquids containing abrasive solids. Diaphragm pumps and plunger pumps can also be used as metering pumps.

More News