NEWS CENTER

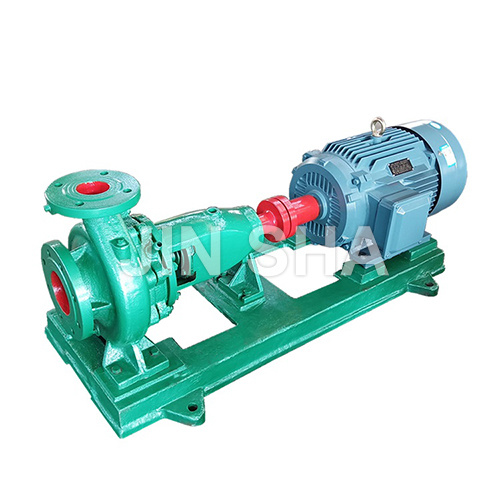

Structure of IS ISR End Suction Pump

Time:

2022-03-30

IS ISR End Suction Pump is mainly composed of pump body, pump cover, impeller, shaft, sealing ring, packing ring and suspension bearing components. The pump body and pump cover of the IS ISR End Suction Pump are split from the back of the impeller, which is the so-called back door structure. The advantage is that the maintenance is convenient, the pump body, the suction pipeline and the discharge pipeline are not moved during maintenance, and the rotor parts can be withdrawn for maintenance.

The casing of the IS ISR End Suction Pump (ie the pump body and the pump cover) constitutes the working chamber of the pump. The impeller, shaft and rolling bearing are the rotors of the pump. The suspension bearing part supports the rotor part of the pump, and the rolling bearing bears the radial force and residual axial force of the pump. In order to balance the axial force of the pump, most pumps are provided with sealing rings at the front and rear cover plates of the impeller, and a balance hole is provided on the rear cover plate of the impeller.

Due to the small axial force of some IS ISR End Suction Pumps, there are no seal rings and balance holes on the back cover of the impeller. The seal of the pump is composed of packing gland, shaft sleeve and packing, etc., or adopts the form of mechanical seal to prevent air intake or a large amount of water leakage. In order to avoid shaft wear, a shaft sleeve is installed to protect the shaft passing through the packing cavity. An O-ring is installed between the shaft sleeve and the shaft to prevent air intake or water leakage along the mating surface. The transmission mode of the pump is connected with the motor through the coupling. The direction of rotation of the pump, viewed from the drive end, is clockwise. The IS ISR End Suction Pump is improved on the basis of the IS type pump. There is a cooling chamber in the pump cover, and the filling part is cooled by normal pressure cold water, so that the temperature of the conveying medium can reach 120℃. In addition, this pump can also be used to transport clean water at room temperature. At this time, it is not necessary to supply water to the cooling chamber, realizing one machine with multiple functions.

More News